Industrial applications

Engineered sealsIndustrial applications

CeraSeals and partners design and manufacture mechanical seals and associated products mainly for renewable energy, oil & gas, chemical, pharmaceutical, food, pulp & paper, dredging, mining, power and many more industrial applications.

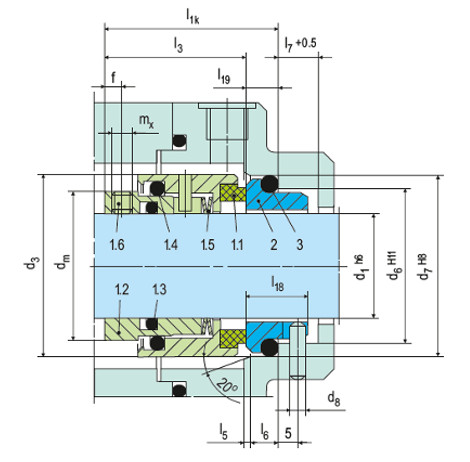

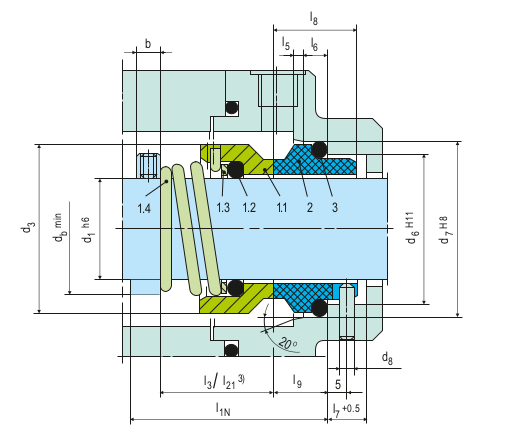

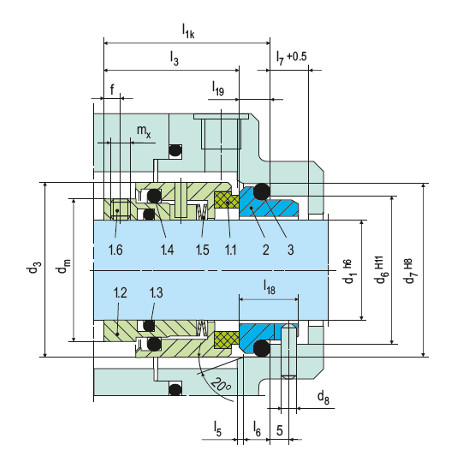

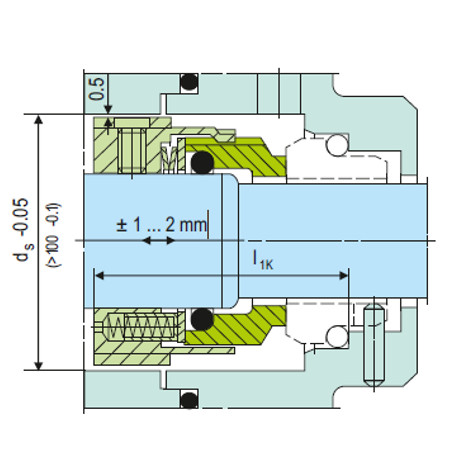

With a wide range of products and services, CeraSeals and partners have solutions for every sealing requirement – such as Pusher Seals, Standard Cartridge Seals, Elastomer Bellows Seals, Metal Bellows Seals, Engineered Seals, Split Seals, Gas-Lubricated Seals and many more.

Each and every CS-Seals product is the result of numerous steps involving extensive engineering and thus processing the same in various production steps. Our engineers at Ceraseals work with discipline and passion to maintain high standards in their respective fields. With the use of 3D modelling we ensure optimum performance of application specific seals.

Ceraseals has engineered high-performance products that reliably withstand extreme environments, challenging applications and evolving legislation. No matter how strict the specification or how unique the application, together we have the solutions to offer.

Sealing Technology

With a wide range of products and services, CeraSeals and partners have solutions for every sealing requirement – such as Pusher Seals, Standard Cartridge Seals, Elastomer Bellows Seals, Metal Bellows Seals, Engineered Seals, Split Seals, Gas-Lubricated Seals and many more.

Food & Sterile Processes

The Food Industry requires the utmost hygiene during the production process. This means the used seals must be food-safe, reliable, and compliant to a great diversity of strict requirements and regulations which may vary per country or region, based on their legislation.Our engi

neered seals are easy to clean, without empty spaces and gaps, so you do not need to dismantle for cleaning . ( SIP/CIP) Our seals also have abrasion resistant surfaces to be compliant towards food-safety regulations.

As soon as food products are shipped internationally, the manufacturer also needs to be compliant towards the legislation and regulations of the targeted countries.

At Ceraseals we completely understand the requirements. Not only the requirements on food safety regulations, but also the requirements in terms of expected long-term reliability and use.

More information on your specific requirements? Just contact us.

Marine

With automation in marine applications and the protection of our seas, the sealing technology is becoming increasingly important. Various different media need to be sealed in the tightest of spaces on board ships: the spectrum of applications in this sphere ranges from fuel supply, fire fighting facilities, bilge and ballast tank pumps right through to tubular stern seals, thru-bulkhead receptacles and flue gas ducts. Many of the seals used in such applications have to be seawater resistant, so in many cases are made from high-quality materials.

Waste Water

Municipal and Industrial sewage is conveyed by waste water pumps into collection tanks at the sewage works. Sewage works pumps are usually operated with single seals in either a dead-end arrangement (conical) seal chamber or with product circulation or external flushing (cylindrical seal chamber). While standard seals are in many cases adequate for applications involving the supply of fresh water or conveyance of waste water, special engineering solutions are a necessity where heavy-duty applications in the spheres of drinking water supply or seawater desalination plants are concerned. On the other hand, thermal energy provision requires individual account to be taken of parameters such as pressure, temperature, sliding velocity, friction, water quality and additives. Their high quality ensures that Ceraseals seals significantly boost the availability of pumps in all types of water-related applications.

Hot Water Pumps

Hot water is conveyed by pumps for a variety of purposes in thermal energy generating systems, district heating systems, home heating systems and so on. The suitability of a mechanical seal for such applications depends on many different parameters, e.g. pressure to be sealed, temperature at the seal, sliding velocity, power consumption, water quality (pH-value, O2-dose, conductivity, operating mode), water additives such as corrosion inhibitors.

Food applications

We produce seals for mash pumps, thick juice pumps, flume water pump & worm type agitator for the sugar industry.

Agglomerators & eccentric pumps for dairy products, spherical dryer for powder processing, as well as centrifugal pumps for liquid foods.